Superior Cut Tolerance:

- High-capacity, high-performance saw ensures throughput

Advanced Automation:

- Servo-controlled gauge head positioning

Safety:

- Floor mounted console or pedestal away from cutting area

- Electronically interlocked saw panels

Substantial Gains:

- Wide table capacity maximizing throughput

Quality Considerations:

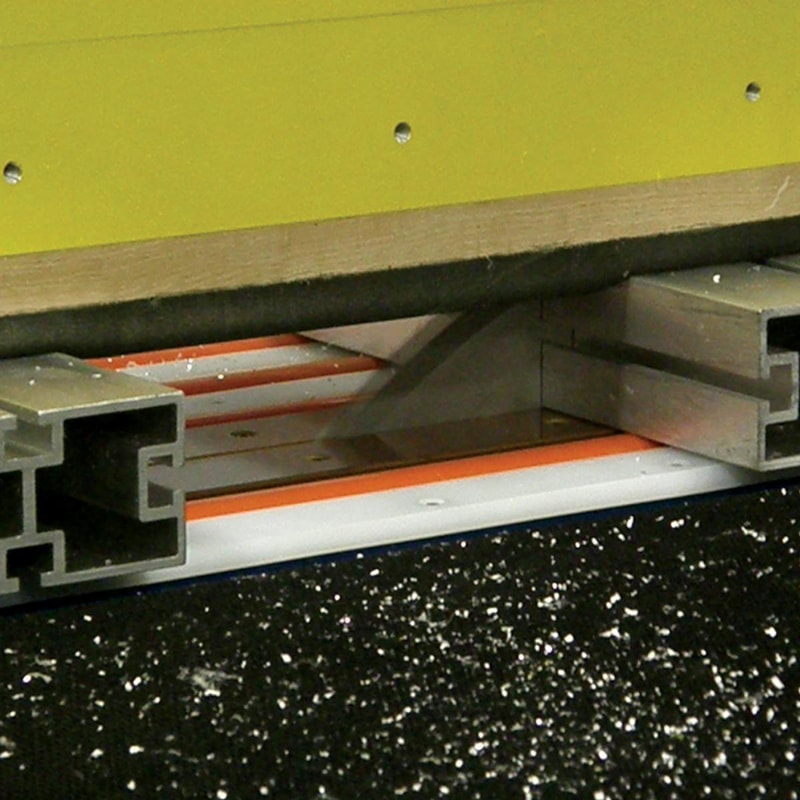

- Drop down arbor design

- Large Diameter Rollers

- Powered roller table

- Chip collector with air valve

- Under-table design

- Removable side panels

- Automatic blade height adjustment

- Excellent cutting tolerances

- “Drop down” arbor design

- Maximum safety

- Minimum noise

- Easy maintenance

- Optimizes blade performance

- Lower tooth angle minimizes impact

- Better cut quality, less damage to thin shapes

- Higher-quality product

- Minimum waste

- Elimination of offline cut

- Eliminates back rake

- Enhances productivity by allowing process to continue while blade is making return stroke