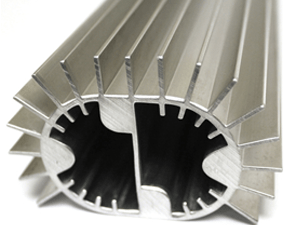

Central Aluminum Company has been a staple of the aluminum manufacturing industry in Ohio since our beginnings in 1963, and our company has set a high standard for quality machining for a wide assortment of industries. For example, recently we were contracted by a client in the automotive industry to fabricate an aluminum extrusion of a transmission cooler body. Using our 6063-T6 aluminum, we employed our advanced machinery, including our extrusion press and precision cut fabrication saw, to cut this part to our client’s exact specifications. After the primary machining was completed, we finished the product with clear anodizing. We made sure that each manufactured piece was inspected for its dimensions and surface quality, assuring that our client would be receiving the highest quality products possible.

To learn more about this project, please see the following table or feel free to Contact us directly.