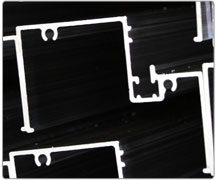

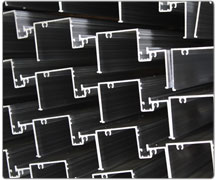

At Central Aluminum Company, we have been serving a wide range of industries with precision-made custom aluminum components for nearly 50 years. Our experience and expertise was put to the test when a client in the construction industry contracted our services to create a 3” male frame aluminum extrusion for a patio room component. Using 6063-T6 aluminum, we employed our extrusion press to extrude and cut this part to the exact dimensions dictated by our customer’s specifications. Our technicians ensured a high quality product with dimensional and surface quality inspections performed during manufacturing, with powder coating applied for an exceptionally durable finish. This project was completed within a turnaround time of 4 weeks for our client in Cleveland, Ohio, and is manufactured in volumes of 1000 lbs. per length, per release.

To learn more about this project, please see the table below, or Contact us directly to find out how we can put our state-of-the-art facility to use for your metal extrusion needs.

Aluminum Extrusion of a Patio Room Component Project Highlights

- Product Description

3 in Male Frame

- Capabilities Applied/Processes

Primary:

Extrusion Press Cut to Length

Secondary:

Powder Coating

- Equipment Used to Manufacture Part

Extrusion press, Powder Coat Line

- Tightest Tolerances

Standard Industry Tolerances

- Material Used

6063-T6 Aluminum

- Material Finish

Powder Coated

- In process testing/inspection performed

Dimensional Inspections

Surface Quality

- Industry for Use

Construction

- Standards Met

Customer Specifications, 2D CAD Drawing

- Product Name

Patio Room Extrusion Component